By Zachary Byrne

June 20, 2024

A Beginner’s Guide to Choosing the Perfect 3D Printing Method

So, you’re thinking about diving into the world of 3D printing? How exciting! Maybe you’ve been inspired to build your own handy gadgets, after seeing the Winter Park Library’s Ultimaker S5 Pro 3D Printer in action, maybe you’re looking to create custom Dungeons and Dragons figures for you and your friends -maybe you want to print figures OF your friends! Whatever your reason is for using 3D printers, one of the first things you'll need to do is pick the kind of 3D printer you want to use.

Wait- so there’s more than one kind of 3D printer? Yup! And we’re here to break down the key differences (pros and cons, if you will) between resin and filament 3D printers, so that you can choose the printer that’s best for you.

This blog won’t cover the software used with 3D printers. Instead, we’re going to talk about the general differences in how each printer works, what they’re capable of, and the costs you can expect to encounter when investing in one of these phenomenal machines.

Now, grab yourself a cup of coffee, sit back, and get ready for today’s fundamental blog post:

Filament Printers

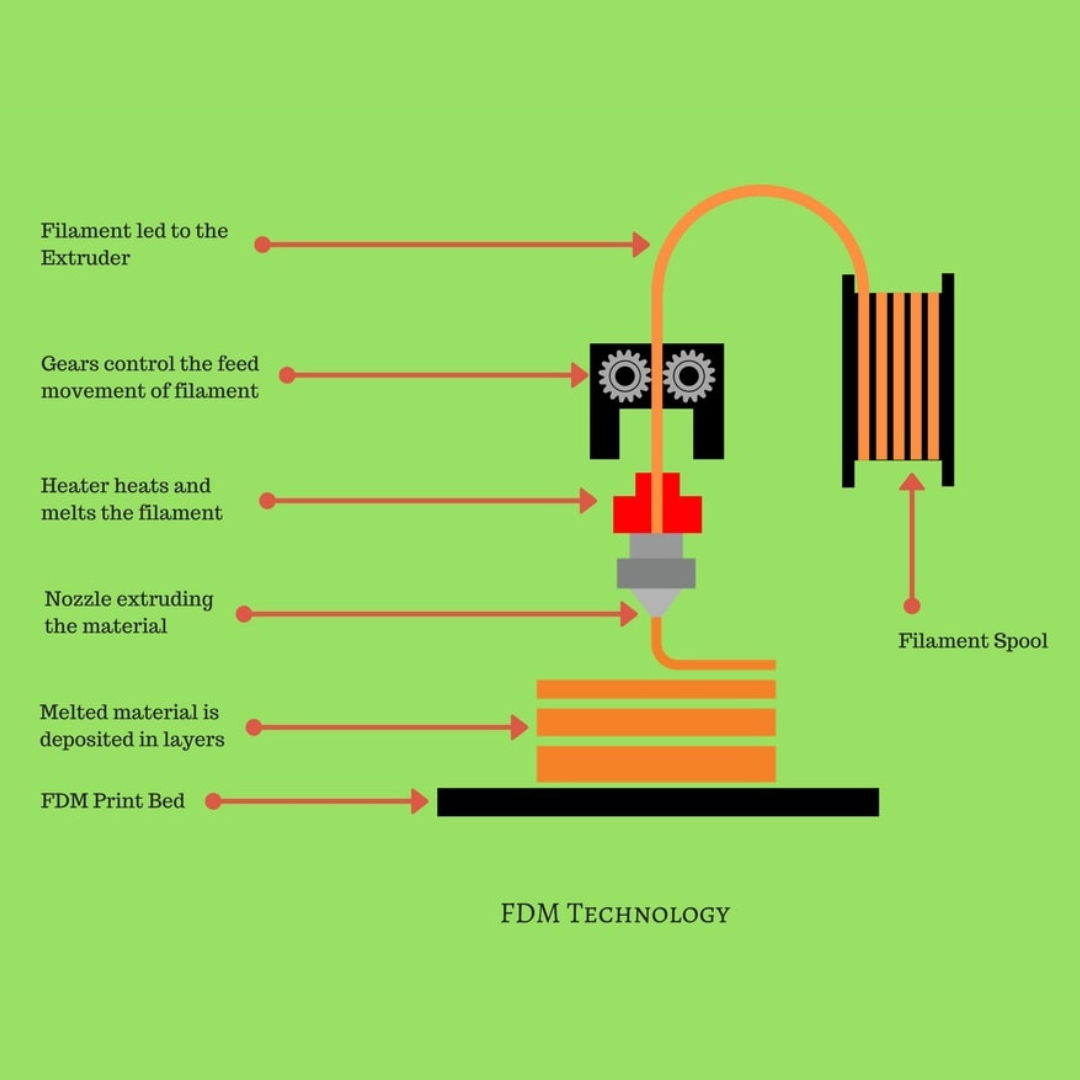

The technical phrase for a filament printer is “Fused Deposition Modeling” printer or “FDM” for short. These are the most common types of 3D printers, and it’s the type we have here in the Winter Park Library’s Dream Room Lab, but what does “FDM” mean?

Well, imagine a hot-glue gun on a mission. Filament printers use a spool of thermoplastic filament (a fancy word for ‘threadlike fiber’), which is melted and squeezed through a nozzle. This nozzle moves around, depositing the melted plastic, layer by layer, to create your object. It’s like building with tiny, hot spaghetti strands that harden as they cool.

Resin Printers

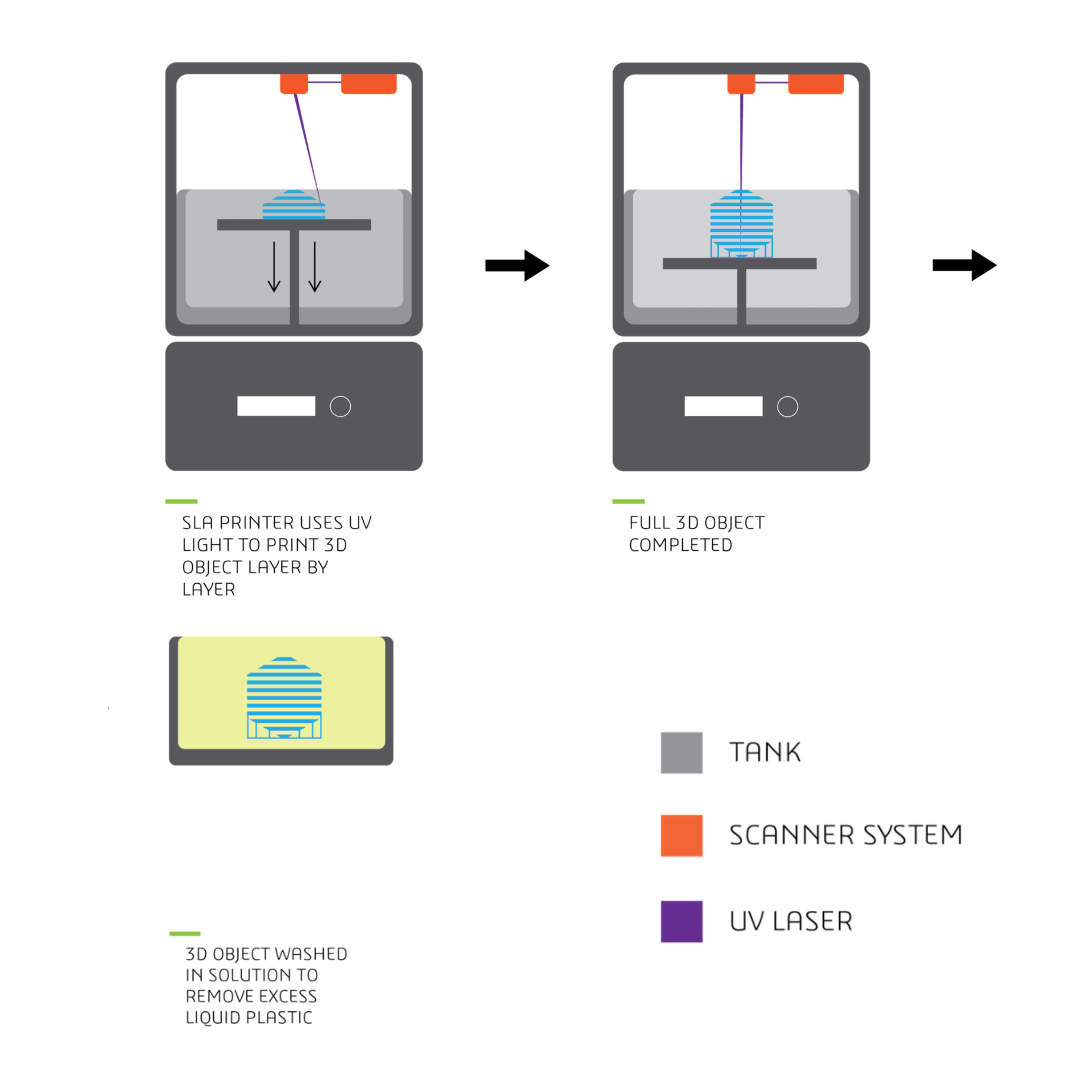

Now, resin printers are a bit more complex in their nature, and there are even different subcategories, but the most common ones use “Stereolithography” and “Digital Light Processing” (abbreviated “SLA” and “DLP,” respectively). These resin printers use a liquid photopolymer resin (a synthetic, plastic-like substance) that is cured by a UV laser or light source. Think of a sci-fi movie where lasers create objects out of thin air, except now the lasers are working within a vat of liquid resin, with each layer solidifying as it’s exposed to light.

Material World: What Do They Use?

Filament Printers

The most commonly used materials in household filament printers are PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene), which are plastic composites. There are also specialty filaments like carbon fiber, wood, metal, and even chocolate!

These materials range from pretty sturdy to surprisingly strong, and can make solid structures for household materials and even commercial machine parts.

Resin Printers

Resins start as liquids and become solid when exposed to UV light. There are a variety of resin subcategories like standard, flexible, tough, castable, biocompatible, and other specialty resins. The resulting prints are often more detailed and have smoother finishes.

Quality Counts: How Detailed Can a Print Be?

Filament Printers

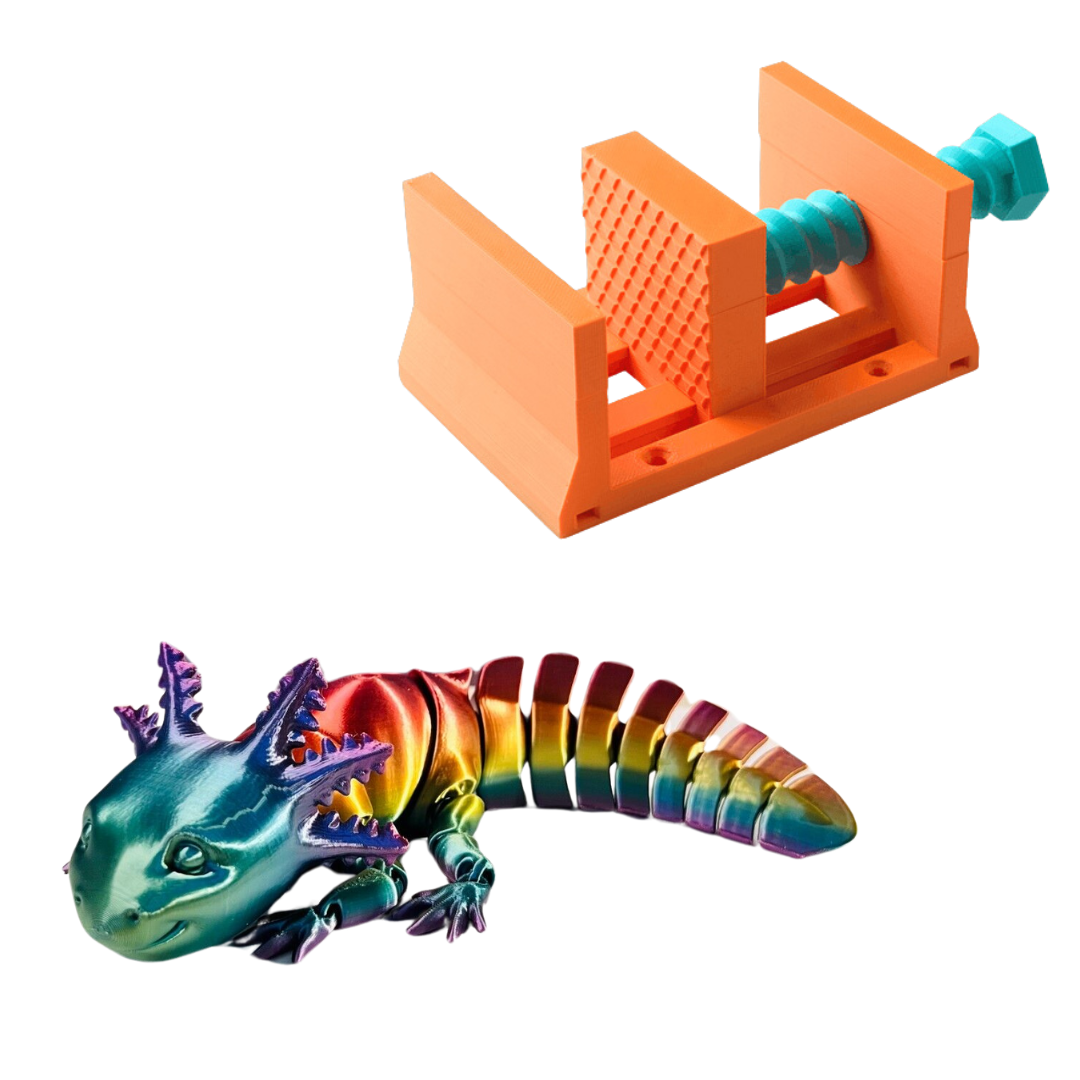

The surface of filament prints will generally feature visible layer lines and are far from water-tight, but you can produce them in a variety of colors and with moving or flexible parts! resulting in very eye-catching designs!

The level of detail or definition that a printer can reach is usually measured in ‘microns,’ with lower numbers meaning a higher definition. In the case of FDM printers, you can expect 100-200 microns and even as low as 50 microns (we’ll have a better scope of understanding once we talk about resin print definition).

Resin Printers

Resin prints are going to be noticeably smoother, with nearly invisible layer lines! To put it in perspective, the average resin print is impressively fine at around 25 microns.

Generally, however, these prints will be more fragile than their filament-based counterparts and won’t often be used for designs that require structural stability. You can count on these prints for the fine detail of board game miniatures, replicas, and other “for show” products!

The Cleanup: Post-Processing (You're Not Done Yet!)

Filament Printers

Once the 3D printing is completed, the post-process is fairly simple – just remove the supports, sand the print as needed, and you’re ready to display your fresh creation!

Resin Printers

The post-processing for a resin print is a bit more involved – you’ll need to rinse and wash the printed model in order to remove any uncured resin, solidify the model under a UV light, remove the supports, and sand as needed. Think of it as giving your print a spa day! Note that resin prints will usually be produced in the grey of resin, so they’ll also require a fresh coat of paint if you want to brighten them up.

Battle of the Budget: How Much Do They Cost?

Filament Printers

Entry-level models start at around a few hundred dollars, with high-end machines going up to $2,000 or more. Typically, you’ll also be spending $20 to $50 per kilogram of standard filaments at a time. Lastly, on occasion, you may need to replace worn or damaged nozzles and print beds, which are generally inexpensive -but the price can vary depending on the specific FDM printer you purchased.

Resin Printers

These sophisticated machines start at around $200 to $500 for entry-level, with mid-range models up to $1,500 and high-end models exceeding $2,000! Your materials are also going to cost a bit more, ranging from $50 to $150 per liter for resins (with specialty resins costing even more). And -you guessed it- maintenance prices will be higher, as well, requiring the replacement of resin tanks and the use of a regular cleaning schedule with isopropyl alcohol. Plus, you’ll need a UV curing station to solidify your models.

The Verdict: Which One’s for You?

Go Filament:

If you’re looking for versatility, lower costs, and ease of use. These 3D printers are ideal for functional parts, prototypes, and larger prints!

Go Resin:

If you crave high detail, smooth surfaces, and are okay with a bit more mess and post-processing. These 3D printers are perfect for miniatures, jewelry, and are even used for dental models!

In the end, no matter which path you choose, both filament and resin printers will open up a world of creative possibilities. If you’d like to see a filament printer first-hand, we have one at the Winter Park Library (I’ve mentioned the Dream Room Lab’s Ultimaker in this blog and now here’s the link!) Dream Room Lab | Winter Park Library

Thanks for reading, and happy printing!